Products

Flow-Through Substrates (Catalyzed or Uncatalyzed)

| Flow Through Substrates | Cell Density/Wall Thickness CPSI/In. | Material | Coefficient of Thermal Expansion (CTE) | Porosity |

|---|---|---|---|---|

| (x 10-6/ºC, RT-800 ºC) | % | |||

| Standard Wall | 300/13 | Cordierite | 1.0 (1.25 Max) | 35 |

| Standard Wall | 400/7 | Cordierite | 1.0 (1.25 Max) | 35 |

| Standard Wall | 300/8 | Cordierite | 1.0 (1.25 Max) | 35 |

| Thin Wall | 350/5.5 | Cordierite | 1.0 (1.25 Max) | 35 |

| Thin Wall | 400/4 | Cordierite | 1.0 (1.25 Max) | 35 |

| Thin Wall | 600/4 | Cordierite | 1.0 (1.25 Max) | 35 |

| Ultra Thin Wall | 600/3 | Cordierite | 1.0 (1.25 Max) | 35 |

| Ultra-Thin Wall | 900/2 | Cordierite | 1.0 (1.25 Max) | 35 |

| * Custom Substrate Assemblies available at request | ||||

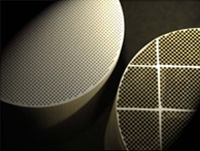

Logical Clean Air Solution's Substrates are extruded honeycomb monoliths containing thousands of parallel channels. The channel walls are coated with precious metal catalysts that convert noxious emissions into less harmful gases and water vapor. Ceramic substrates are used at the heart of catalytic converters to help reduce exhaust emissions from Diesel and gasoline-powered engines.

Our Ceramic substrates and filters are used around the world in diverse applications across the pollution abatement industry to help customers achieve efficiencies, reduce particulate matter, and improve performance in new and retrofit stationary emissions control systems.

Our products are available in cell densities, diameters and lengths that are among the most diverse in the industry.

Our substrates enable highly efficient emissions control systems by offering:

- High surface area

- Low pressure drop

- Rapid light-off

- Thermal-mechanical durability

- System cost efficiency

High Temperature Durability

Exhaust gases can reach extreme temperatures and are highly variable, producing thermal stresses within the converter. The ceramic composition used in our substrates is highly resistant to thermal shock resulting from sudden and severe temperature changes. In addition, these advanced substrates can operate effectively at temperatures of 1200C and can withstand spikes of up to 1400C.

Mechanical Durability

Cordierite Ceramic Substrates have proven mechanical durability. Their monolithic (single-piece) structure and cellular geometry promote stiffness and isostatic strength.

Thin-Wall & UltraThin-Wall Substrates

The higher geometric surface area of Thin-Wall & Ultrathin-Wall substrates contributes to lower emissions during steady-state catalytic converter operation. In addition, their lower mass facilitates quicker converter light off for more effective cold-start emissions reductions.

With their thinner walls, Thin-Wall & UltraThin-Wall substrates also offer the option of improved pressure drop performance. Compared to a 600/4 thin-wall substrate, and Ultrathin-Wall 600/3 substrate delivers approximately the same geometric surface area with 10% lower pressure drop.

Diesel Particulate Filters DPF (wall-flow)

| Diesel Particulate Filters | Cell Density/Wall Thickness | Diameters | Material | Coefficient of Thermal Expansion (CTE) | Porosity |

|---|---|---|---|---|---|

| CPSI/In. | from - to | (x 10-6/ºC, RT-800 ºC) | % | ||

| Passenger/Light Duty | 300/13 | 5" - 13" | Aluminum Titanate | 1.0 | 50 |

| High Soot Mass Limit | 300/13 | 5" - 13" | Aluminum Titanate | 1.0 | 50 |

| Thin Wall/Low Porosity | 300/10 | 5" - 13" | Aluminum Titanate | 1.0 | 50 |

| Heavy Duty/High Durability | 300/13 | 5" - 13" | Aluminum Titanate | 1.0 | 50 |

| Heavy Duty/Pressure Drop | 200/12 | 7.5" - 13" | Advanced Cordierite | .5 | 50 |

| Heavy Duty/Pressure Drop | 200/18 | 7.5" - 13" | Advanced Cordierite | .5 | 50 |

| Heavy Duty/Pressure Drop | 300/15 | 7.5" - 13" | Advanced Cordierite | .5 | 50 |

| * Custom Filter Assemblies available at request | |||||

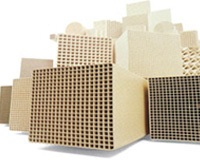

Our diesel particulate filters utilize Advanced Cordierite or Aluminum Titanate wall-flow monoliths to trap the soot produced by diesel engines. The cylindrical filter element consists of many square parallel channels running in the axial direction, separated by thin porous walls. The channels are open at one end, but plugged at the other. This way the particle laden exhaust gases are forced to flow through the walls. Gas is able to escape through the pores in the wall material. Particulates, however, are too large to escape and are trapped in the filter walls.

Logical Clean Air Solutions provides Diesel Particulate Filters (DPF) for various applications:

- On-Road Light/Medium/Heavy-Duty Vehicles

- Power Generation

- Dust Control

- Mining Equipment

- Construction

- Marine

- Material Handling

- Locomotive

Diesel Oxidation Catalyst (Flow-Through) Catalyzed or Uncatalyzed

| Diesel Oxidation Catalyst | Cell Density/Wall Thickness | Diameters | Material | Coefficient of Thermal Expansion (CTE) | Porosity |

|---|---|---|---|---|---|

| CPSI/In. | from - to | (x 10-6/ºC, RT-800 ºC) | % | ||

| Standard Wall Diesel | 300/8 | 5" - 13" | Cordierite | 1.0 (1.25 Max) | 35 |

| Standard Wall Diesel | 400/7 | 5" - 13" | Cordierite | 1.0 (1.25 Max) | 35 |

| Thin Wall Diesel | 400/4 | 5" - 13" | Cordierite | 1.0 (1.25 Max) | 35 |

| Thin Wall Diesel | 300/5 | 7.5" - 13" | Cordierite | 1.0 (1.25 Max) | 35 |

The diesel oxidation catalyst (DOC), or Two-Way, owes its name to its ability to promote oxidation of several exhaust gas components by oxygen, which is present in ample quantities in diesel exhaust. When passed over an oxidation catalyst, the following diesel pollutants can be oxidized to harmless products, and thus can be controlled using the DOC:

- carbon monoxide (CO),

- gas phase hydrocarbons (HC),

- organic fraction of diesel particulates (SOF).

Additional benefits of the DOC include oxidation of several non-regulated, HC-derived emissions, such as aldehydes or PAHs, as well as reduction or elimination of the odor of diesel exhaust.

The emission reductions in the DOC occur through chemical oxidation of pollutants occurring over the active catalytic sites. These processes can be described by the following chemical reactions.

(1) [Hydrocarbons] + O2 = CO2 + H2O

(1a) CnH2m + (n + m/2)O2 = nCO2 + mH2O

(2) CO + 1/2O2 = CO2

Stationary Flow-Through Substrates (Catalyzed or Uncatalyzed)

| Stationary Substrates | Cell Density/Wall Thickness | Material | Coefficient of Thermal Expansion (CTE) | Porosity |

|---|---|---|---|---|

| CPSI/In. | (x 10-6/ºC, RT-800 ºC) | % | ||

| Thin Wall | 64/12 | Cordierite | 1.0 (1.25 Max) | 35 |

| Standard Wall | 100/15 | Cordierite | 1.0 (1.25 Max) | 35 |

| Thin Wall | 230/7 | Cordierite | 1.0 (1.25 Max) | 35 |

| Standard Wall | 400/7 | Cordierite | 1.0 (1.25 Max) | 35 |

Examples of Non-Road (Stationary) Emissions Applications:

- Hot Gas Filtration

- Cloud Chamber

- Industrial Boilers

- Dust Collectors

- NOx Scrubbers

- Incinerators

- Power Plans

- Steel Mills

- Smelters

- Cement Plants

- Oil Refineries

- Printing or paint Shops

SCR & NSCR Catalysts

Logical Clean Air Solutions provides SCR, NSCR, and Pre-Extruded SCR Catalysts for Emission Control Manufacturers to reduce cost and improve quality of systems. We offer ceramic honeycomb SCR catalyst for the power generation, petro-chemical and industrial processing industries worldwide. Our unique catalyst management product features include:

- High NOx removal activity

- Low pressure drop & ammonia slip

- High resistance to poisoning and erosion

- Low SO2 conversion rate

- High durability & stability

Our honeycomb construction offers higher mechanical strength for catalyst durability in addition to an efficient geometry for high surface area and low-pressure loss. We determine the honeycomb structure and cell pitch for each customer application following an engineered analysis of system performance requirements. Our catalysts are versatile and can be operated over a wide temperature range and provide excellent resistance to sulfur, poisons, and erosion, resulting in long life and low overall cost to the customer.

Custom Substrate & Filter Assemblies

For those large applications that require filter diameters over 13", we have customized filter options for you. Logical Clean Air Solutions offers made-to-order substrates and diesel particulate filters for use in various emission applications.

Customized Ceramic Filters are typically used in:

- Heavy Duty Diesel Applications

- Mining Equipment

- Chemical Plants

- Marine Engines

- Refineries

- Dust Collection

- Biomass Gasification

- Catalytic Gas Treatment

- Dry Scrubbing

- Incineration