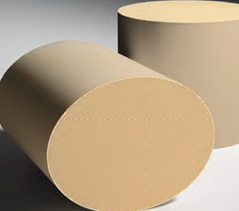

A One-Stop Source for all the most innovative emission control technologies. Whether you're in need of solutions to meet the latest emissions regulations, or an emissions equipment manufacturer looking for advanced filters, substrates and custom filter assemblies, Logical Clean Air Solutions is the right place for you.

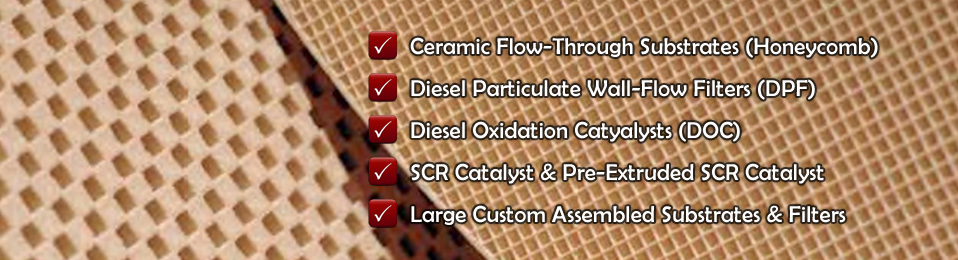

Our Products

Diesel Retrofitting Bus & Truck Fleets

Listen to What Purchasing Buyers are Saying

-

Logical has been our primary supplier of Ceramic Substrates for at least six years. Their high quality, and most importantly low prices have enabled us to compete and grow within our very aggressive market.

Ernesto Domingo S.

-

We have worked with Logical for over 10 years. They are always reliable and efficient in delivering the best quality substrates on the market.

Charlie C.

-

Our business has greatly expanded ever since we met Logical Clean Air. They offer custom sized filters that you cannot find anywhere in the world.

Bruce G.